Analysis Report

- Categories:Technology

- Author:

- Origin:

- Time of issue:2021-11-02 13:39

- Views:

(Summary description)

Analysis Report

(Summary description)

- Categories:Technology

- Author:

- Origin:

- Time of issue:2021-11-02 13:39

- Views:

² Trouble description

We received the order from owner to carry out the inspection of ME cylinder liner& piston crown abnormally high worn value condition, the trouble shown:

l The engine date(See Fig.1)

Fig.1

Total running hours: 24933.9

During ME cyl. Overhauling, the shipyard operator measured the cyl. Liner& piston crown, the measured record shown:

All piston crown the 1st piston groove clearance out of range, the min. Clearance were found in 0.75mm, the

max. Clearance achieved to 2.2mm, No.4 piston crown 1st groove inner surface already appearedstep

condition.

The cyl. Liner worn value max. = 1.71mm (in 1st ring TDC position)

As the computational formula: 1.71mm/24933.9hrs*1000hrs=0.06858mm, in normal range, but the

liner lower position worn also found more than 1.50mm.

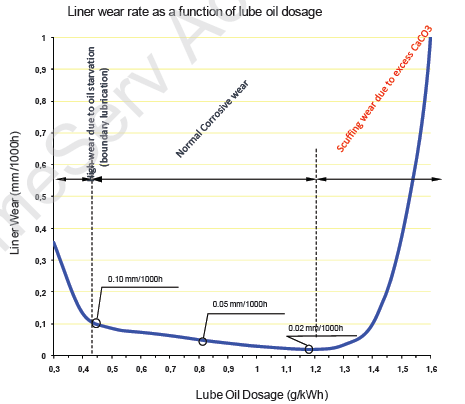

The cylinder liner wear rate instruction (See Fig.2)

Fig.2

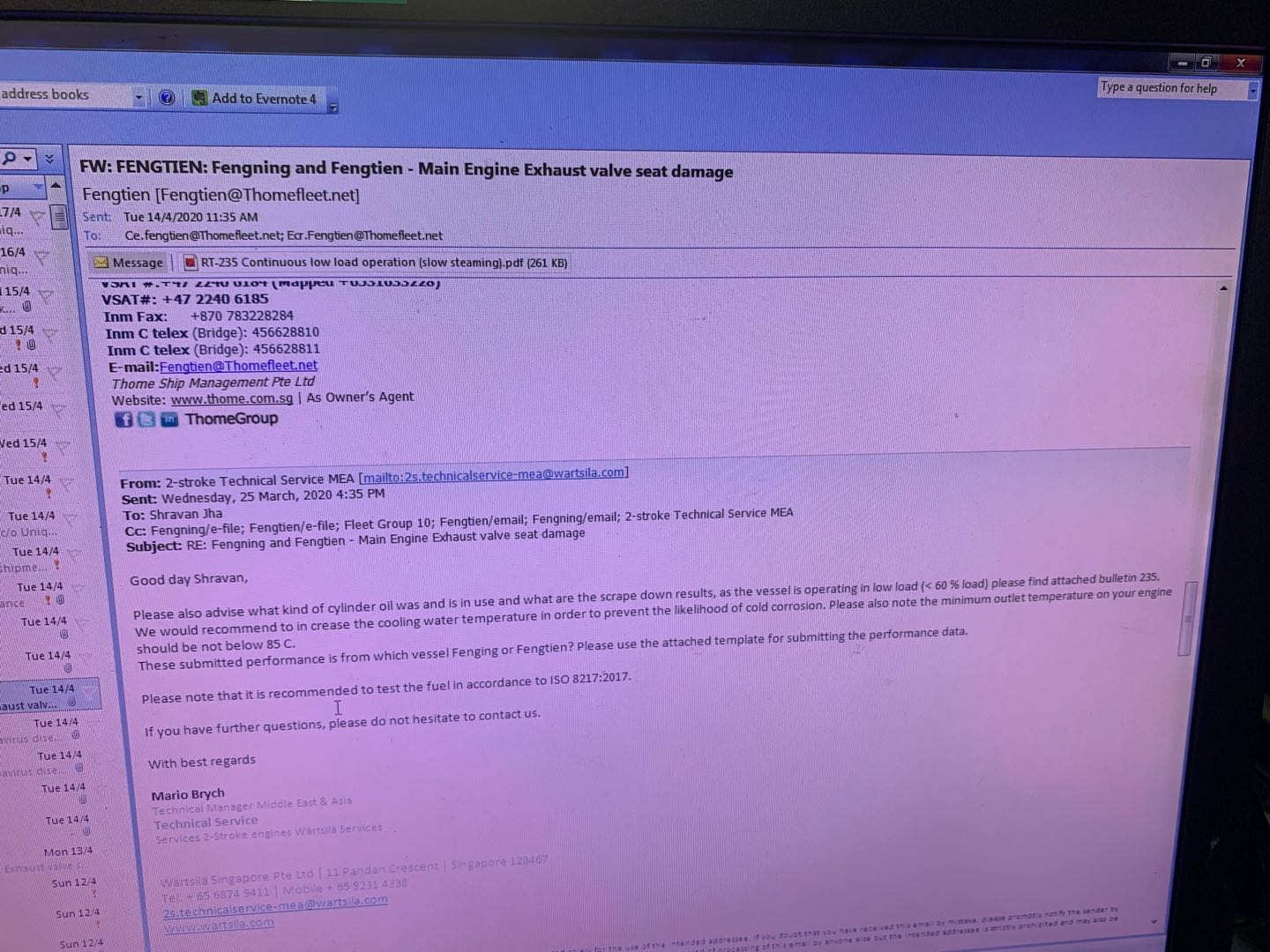

The Exhaust v/v seat corrosion (See Fig.3)

Fig.3

By the way, how about the economizer condition?

Analysis

1.About the exhaust v/v seat abnormally corrosion, the appearance of seat surface corrosion were found highly similar with acid corrosion, the engine log no found long period any high temp. Alarm, during ABB service team carried out turbocharger overhauling, the turbo. Also found high radial clearance and the nozzle ring blades found slightly damaged, ABB service team can not explain this appearance, there is a good reason to suspect ME meet with long time cold corrosion.

If the cold corrosion happened, the cyl. Liner also should be in high wear rate in lower position(scavenge air ports),the cold corrosion maybe not effect the TDC position caused by the precipitated acid liquor down flow;

2.For the cylinder liner, the top position(TDC) found 1.71mm wear rate should be in normal range after about 2,5000Hrs running, but the lower position(such as scavenge air port) also found high wear rate, during engine running, the normally wear rate should be in lower range(top position=1.71mm,the bottom should be below 0.50mm----this vessel cyl. Lub. Oil feed rate were set in 0.95g/KWh).

The cyl. Liner found abnormally wear condition, as piston ring inspection result shown, the piston ring breath surface all found in brightly condition without any scratch, its means the piston ring in good running condition with enough cyl. Lub. Feed rate, for the abnormally wear condition, there is good reason to suspect the liner meet with cold corrosion.

3.The shape of piston ring groove normally worn should look like the horn mouth, the step which found in No.4 piston crown 1st groove should be caused by corrosion, if the corrosion happened, the thickness of piston ring should be also found abnormally reduce.

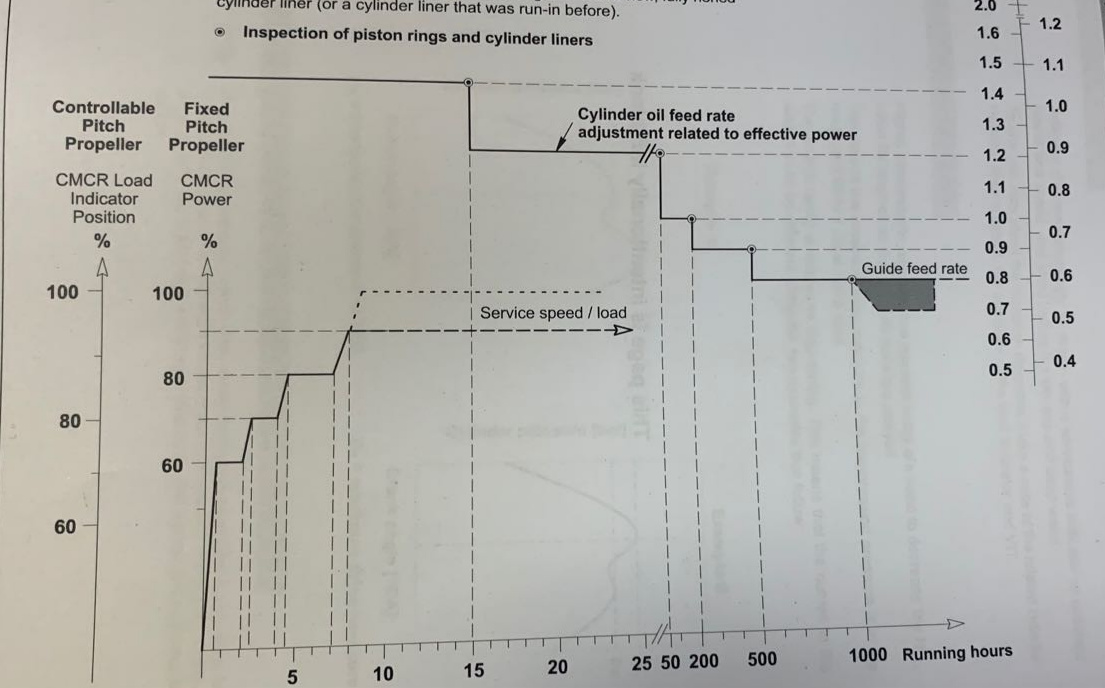

4.As the performance of C/E supplied, our engine the most time running in low load(lower than 60% CMCR, this condition may in good fuel consumption),the exh. Temp. May long time below 250℃, its easily to happen cold corrosion(HFO S>0.5%),according to Wartsila Technical Bulletin RT-235.

Above the appearance, there is great possibility to confirm, our engine met with cold corrosion, the Wartsila bulletin RT-235 were received at Mar.25.2020(See Fig.4),its means we improved the engine running condition follow the instruction RT-235 only half month, the cold corrosion condition already kept long time running.

Fig.4

Suggestions

1. The feed rate ofcylinder lubricator should be adjusted follow enginerunning-in

procedure after cylinder overhauling (See Fig.5)

Fig.5

2. Due to different kind of F.O, such as HFO,LSFO...,follow Win GD SL-0009,the viscosity of

FO pump inlet must be set in the range 10-20 °cSt, Win GD recommends to maintain the

viscosity at the lower end of the range 13-17cSt as specified in the engine Operation

Manual, without exceeding 150℃ at the engine inlet. Sufficient trace heating of the fuel

system on the engine must be ensured.

We have to enhance the bunker quality assay, confirm the new LSFO quality be up to the engine requirement, it is said, there is already appeared the LSFO which found the viscosity lower than 50cSt during the bunker, the viscosity is more important to ensure engine parts running in low wear rate condition. The F.O injection v/v, ICU, F.O pump maybe found high wear rate condition for long time running with lower viscosity fuel.

3.For diesel engines the LT cooling water set point to be kept near limit of the nominal range e.g.36℃ to minimize effects of possible cold corrosion.

4. The cylinder cooling water inlet temp. Should be set follow SL-0009(C/E already changed).

5. The Exh. Gas temp. After cylinder should be kept above 250℃ in order to avoid cold

corrosion, if the exhaust temp. Still drops below 250℃ after above setting carried out, the

engine loading should be increased if feasible.

Other setting please follow SL-0009.

Article reprinted form:MarinSmart Platform

Author:CCC—Zhi wei Zhong

Please indicate the source for reprinting articles

Scan the QR code to read on your phone

CONTACT US

WinKong Marine Engineering Co., Ltd.

Address: 15-19F, Zhongxin Building No. 263 Liaoning Road, Qingdao, Shandong Province, China, 266012

E-mail: newmkt@winkong.net

Fax: +86-532-83807505

Tel: +86-0532-83838072/+86-18863991891

Qingdao Free Trade Zone MarinSmart Supply Chain Co., Ltd.

Address: 8101-1-6(A), 1st floor, Qiantongyuan Building, No.44 Moscow Road, Qianwan bonded area, Shandong Province, China, SDPFTZ

Qingdao MarinSmart Technology Co., Ltd.

Address: 15-19F, No.263 Liaoning Road, Shibei District, Qingdao, Shandong Province, China

Qingdao Winkong Invest & Developing Co., ltd.

Address: 1702 Room, Zhongxin Building No. 263 Liaoning Road, Qingdao, Shandong Province

Qingdao MarinSmart Ship Design Institute Co., Ltd.

Address: 16F-B, No.263 Liaoning Road, Shibei District, Qingdao, Shandong Province,China.

Qingdao Global Marine Safetycare Technology Co., Ltd.

Address: Shandong University of Science and Technology, No. 579 Qianwangang Road, Huangdao district, Qingdao, Shandong Province,China.

MarinSmart Global Service Pte. Ltd.

Address: 2 Jurong East Street 21 #04-21C IMM Building Singapore 609601

© Winkong Marine Engineering Co.,Ltd. 鲁ICP备06011101号 Powered by 300.cn