PMI sensor 见解

- Categories:Technology

- Author:

- Origin:

- Time of issue:2021-11-02 13:34

- Views:

(Summary description)

PMI sensor 见解

(Summary description)

- Categories:Technology

- Author:

- Origin:

- Time of issue:2021-11-02 13:34

- Views:

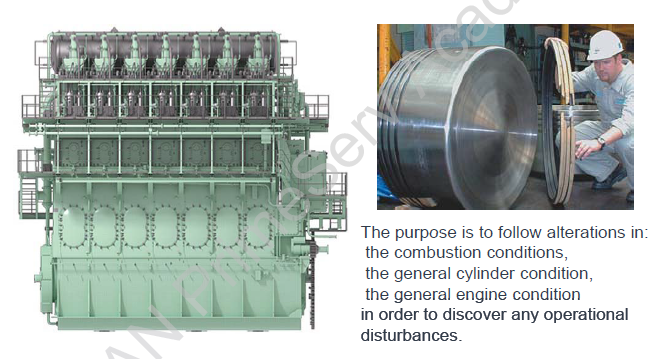

1. The design intention of the PMI system

In a word, the PMI system is beneficial to improve the performance condition of main engine, improve fuel economy, and find abnormalities during the main engine running.

After a long period of development and improvement, the PMI system has already been the standard configuration of the ME engine.

2. Introduction to PMI system

1. Pmax sensor

Pmax is currently set 2 types, which are manufactured by ABB and Kistler . As above photo shown, ABB claims that there is no need for regular calibration during overall life cycle . The ABB type is integrated design with indicator cock, and cannot be replaced separately. Kistler satisfied theoretically the requirements of modification. The sensor and the indicator are designed separately. As Kistler`s instruction, the calibration cycle should been under 4-6 months. IMO requires the sensor should be calibrated annually. Therefore, the most versions choice were found be Kistler version.

As SL-621 shown, the Pmax sensor is wrapped with insulation layer. If the insulation layer is lost, the sensor is exposed to the external environment. If the external temperature is lower than inner space, is`s easily found damaged which caused by low-temperature corrosion, Therefore, the external insulation layer is very important and cannot be lost;

As SL-658 shown, the indicator cock should never be opened during the engine is running even if the cock leakage, otherwise it is very likely to damage the Pmax sensor.

during the offline device connected, you have to connect the coupling firstly, then turn on the cock, the cover nut of cock should be closed during daily operation。

In conclusion, during the main engine prepared standby cycle, the indicator valve is opened. Do not blow the engine with “Air Run” mode, only “Slow turn” mode should be carried out. Moreover,the main engine should carry out blowing the engine with slow turn mode under long time engine stay , The operating times and blowing period can be kept longer appropriately. There is a certain basis for the argument that slow turn blowing will consumes more air, but it only indicates that the operator wants to reach the ignition revolution of the main engine during engine blowing, the less flow slow turn valve with indicator cock vented, the blowing air consumption may be larger (the air consumption were less than Air run under the same execution time with same operating period), but the purpose of engine blowing were not revolution speed, its should be confirmed no foreign matter in the cylinder liner space and rotation system in normal condition, finally confirmed the engine preparation for starting were available. The correct mode of engine blowing should been in Slow turn.

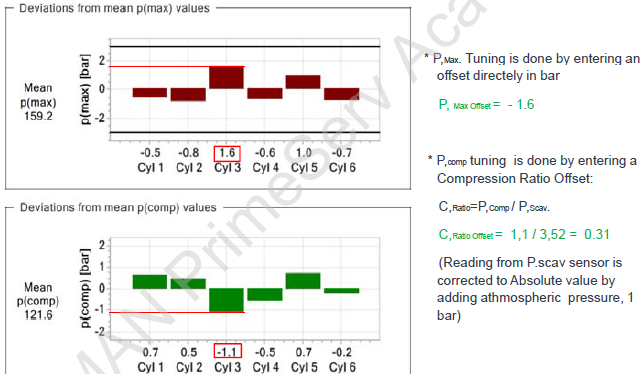

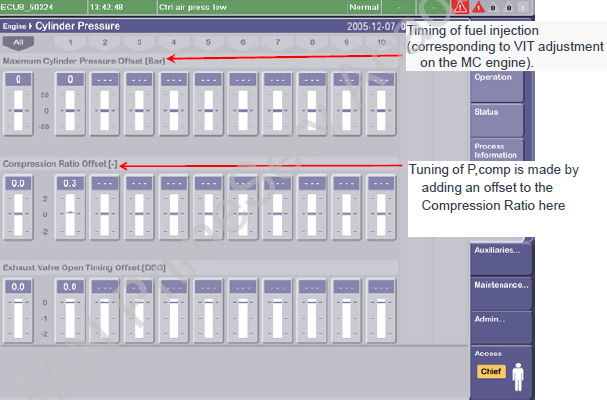

三、Balanced plot, Pmax-Pcomp.

Adjustment calculation method:

Pi: ΔPi / Pi(mea.) * 100% = Δ?

It can be input directly with the system. Allowable adjustment range≦±0.5bar

Pcom: ΔPcom / (Pscav.+1*standard atmospheric pressure) = Δ?

It can be directly input to the system. Allowable adjustment range≦±3bar

Pmax: ΔPmax ≦ 3bar

Adjustment sequence: Pmax. > Pi > Pcomp.

Adjust the frequency:

Pmax--frequently Pi ---due to FQA Pcomp --- cautious

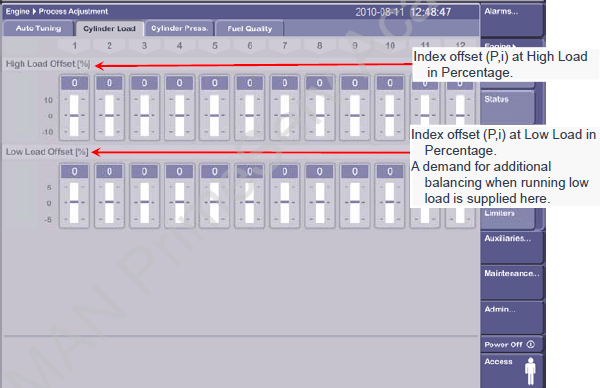

The demarcation point of engine high load&low load is—— low < 50% < high

Anyway, the adjustment of engine should be based on the engine MOP display load (set point) and actual load (derived from PMI calculation—estimated load) under the similar load indicating(±2%) , otherwise the engine may have serious problems.

Fuel Index Adjustment:

Fuel Index Adjustment: Fuel index adjustment changes the index value and FO timing. It is not recommended to change the exhaust temperature.

Pmax、Pcomp Adjustment

PMI Auto-tuning

PMI Auto-tuning must be based on adjusting the engine MOP display load (set point) with FQA to be equal to the actual load calculated by PMI(estimated load)!

The purpose of PMI Auto-tuning is to control emissions and reduce fuel consumption. Pmax is increased by 1 bar and fuel consumption is reduced by 0.2~0.3g/kwh.

CoCoS-EDS:

The early version (basic) cannot communicate with other systems. The later version is equivalent to the engine's VDR, which can back up all the alarms and normal data of the engine's operation, providing a basis for remote data analysis.

Article reprinted form:MarinSmart Platform

Author:Control Commond Console—Zhiwei Zhong

Please indicate the source for reprinting articles

Scan the QR code to read on your phone

CONTACT US

WinKong Marine Engineering Co., Ltd.

Address: 15-19F, Zhongxin Building No. 263 Liaoning Road, Qingdao, Shandong Province, China, 266012

E-mail: newmkt@winkong.net

Fax: +86-532-83807505

Tel: +86-0532-83838072/+86-18863991891

Qingdao Free Trade Zone MarinSmart Supply Chain Co., Ltd.

Address: 8101-1-6(A), 1st floor, Qiantongyuan Building, No.44 Moscow Road, Qianwan bonded area, Shandong Province, China, SDPFTZ

Qingdao MarinSmart Technology Co., Ltd.

Address: 15-19F, No.263 Liaoning Road, Shibei District, Qingdao, Shandong Province, China

Qingdao Winkong Invest & Developing Co., ltd.

Address: 1702 Room, Zhongxin Building No. 263 Liaoning Road, Qingdao, Shandong Province

Qingdao MarinSmart Ship Design Institute Co., Ltd.

Address: 16F-B, No.263 Liaoning Road, Shibei District, Qingdao, Shandong Province,China.

Qingdao Global Marine Safetycare Technology Co., Ltd.

Address: Shandong University of Science and Technology, No. 579 Qianwangang Road, Huangdao district, Qingdao, Shandong Province,China.

MarinSmart Global Service Pte. Ltd.

Address: 2 Jurong East Street 21 #04-21C IMM Building Singapore 609601

© Winkong Marine Engineering Co.,Ltd. 鲁ICP备06011101号 Powered by 300.cn