TRO alarm troubleshooting

- Categories:Technology

- Author:

- Origin:

- Time of issue:2021-11-02 13:45

- Views:

(Summary description)

TRO alarm troubleshooting

(Summary description)

- Categories:Technology

- Author:

- Origin:

- Time of issue:2021-11-02 13:45

- Views:

When the system runs ballast operation and TRO low alarm occurs, the following checks should be carried out:

1. Check the sampling circulation piping of the BWTS

1) Sampling path:

(sampling water is taken out from sampling port and pressurized by sampling air pump before being sent to monitoring unit, a small amount of water into CLX for TRO detection, the rest of the water cycle back to the main system).

2) Since it is a sampling cycle test, Each test of TRO value is a test cycle. Minimum sampling water flow rate is generally required: sampled water can be taken from the main pipeline and flow back during each test cycle.

3) Sampling water velocity can be judged by listening to the working sound of the air pump:

(1) Normal: dull sound with load, about 2~3 times every 2 seconds.

(2) Blocked: in that case, generally air pump does not ring or just ring once for a long time (dozens of seconds);

(3) No water: sounds comparatively light and fast, about 2 times per second.

4) Sampling water is blocked:

(1) It is necessary to check whether the manual valve on the sampling pipe line and the internal electromagnetic is opened (see Appendix I for solenoid valve maintenance) ;

(2) Need to check the Y filter on the sampling pipeline;

(3) Check whether the control air and diaphragm is damaged (general diaphragm damage will cause water leakage) (diaphragm replacement see Appendix II).

2. Check CLX agents

1) Check whether the added time of CLX drug is longer than 2 months. If it is longer than 2 months,the drug should be changed (see Appendix III).

2) If the drug is in the period of validity, clean the dosing pipe system, And after the cleaning is finished: press PRIME and ENTER together to discharge the air and clean water in the dosing pipe system, and the drug can be seen entering in the detection glass wall (if the drug does not not ENTER, the dosing pipe should be flushed several times).

3. Observe whether the sampled water in the CLX detection chamber turns red

1) If no water enters the detection chamber, check step 1 (as above). If step 1 is completed and normal, check as follows.

As shown in the figure, 1 is the flow control valve, turn outwardly to reduce the flow, turn inward to increase the flow; 2 is solenoid valve for sampling water into the detection chamber, can be open and clean; 3 is drainage (hold) solenoid valve, if water flow through the detection chamber can be observed but can not keep, it need to be cleaned; 4 is CLX inlet water filter and should be cleaned at least once every two months.

1) If the glass detection chamber is pink (light red), please check steps 1,2,3. If steps 1,2,3 are normal, then check as follows:

(1) PRIME+ Enter (<--) once, check whether the first TRO value becomes significantly larger (about 1~3ppm) after PRIME, and whether the sampled water in CLX drain pipe turns red during PRIME, and determine whether the sampled water contains TRO. Clean the injection line and check valve if the TRO value becomes large or the sampled water in the drain tube becomes significantly red. As shown in the figure belowed:

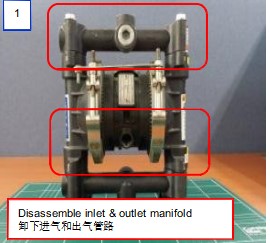

PICTURE 1

PICTURE 2

(2) As shown in Figure 1, after the main pump is removed, the injection pipe in part A can be seen. After the injection pipe is taken out, As shown in Figure 2, and the white part is a one-way valve. Part B of the one way valve is the main component and needs to be cleaned. Cleaning method: soak in warm water and then rub with wet clean cloth until there is no dirt when observe toward light, and then dry.

(3) After cleaning, reinstall.

4.The CLX inspection

1) Observe the sample water in the CLX detection chamber. If it turns dark red and the CLX TRO value remains low,the CLX should be restored to factory settings. To reset the CLX, you need to press "↑" and "ENTER" at the same time, waiting the CLX screen blink once (3S) to restore the factory settings.

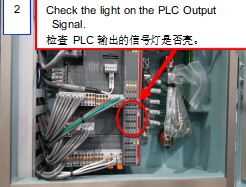

2) Judgement for 4 to 20mA communication and RS485 communication. As shown in the following figure, no wiring (only one set of RS485 cables) is used for RS485 communication. If the wiring is the same as that in the figure 2, it is used for 4 to 20mA communication.

3) Step for setting parameters

After restoring to factory settings, wait for the position indicated in the following figure (→) move to AUTO, press MODE/EXIT, move to CONFIG, and then press ENTER(<--) to enter parameter settings. You can use the key(↕)to select parameter values. Use the ENTER (<--) key to confirm the parameter value and go to the next parameter.

4) Verify the CLX test value after restoring factory settings.

5. When ballasting, TRO high alarm is generally the valve of the main ballast system is opened wrong, resulting in the circulation of ballast water electrolysis.

二.(Deballast operation)

When the system runs in deballast opertion and TRO high alarm occurs, the following checks should be carried out:

1. Check the dispensing unit

1) When discharging ballast, neutralizing agent (sodium thiosulfate) is added by dispensing unit to neutralize TRO in ballast water, so that the discharged ballast water does not contain TRO and protect the creatures in port waters.

2) Dosing process:

3) When an alarm occurs, the following checks are required:

(1) Check whether dispensing unit can throw the drug (observe the one-way ball valve at the outlet of dispensing unit internal injection pump, 1, jumping to throw the drug, 2, not jumping, not to throw the drug). If the drug cannot be thrown, check the dispensing unit internal solenoid valve and the injection pipe system (valve).

(2) Check whether drug in the dispensing unit has crystallized or expired (more than one year after adding the drug). If so, clean the dispensing unit drug tank and refill the drug (see Appendix IV).

2.Check the sampling circulation piping of BWTS:

1) Sampling path:

(sampling water is taken out from sampling port and pressurized by sampling air pump before being sent to monitoring unit, a small amount of water into CLX for TRO detection, the rest of the water cycle back to the main system).

2) Since it is a sampling cycle test, each test of TRO value is a test cycle. Minimum sampling water flow rate is generally required: sampled water can be taken from the main pipeline and flow back during each test cycle.

3) Sampling water velocity can be judged by listening to the working sound of the air pump:

(1) Normal: dull sound with load, about 2~3 times every 2 seconds.

(2) Blocked: in that case, generally air pump does not ring or just ring once for a long time (dozens of seconds);

(3) No water: sounds comparatively light and fast, about 2 times per second.

4) Sampling water is blocked:

(1) It is necessary to check whether the manual valve on the sampling pipe line and the internal electromagnetic is opened (see Appendix I for solenoid valve maintenance) ;

(2) Need to check the Y filter on the sampling pipeline

(3) Check whether the control air and diaphragm is damaged (general diaphragm damage will cause water leakage) (diaphragm replacement see Appendix II).

Appendix I Solenoid valve maintenance

· In case power is not supplied to Sol.V/V..

· In case sampling is not properly done even after power on.

Appendix II Air Pump maintenance

Air Pump Unit does not work.

Malfunction of Air Pump can be caused by the lack of air supply.

Malfunction of Air Pump can be caused by blockage of discharge line.

(1) In case the Y filter is installed on the discharge line, disassemble it to overhaul and clean.

(2) In case of the discharge line blockage, disassemble and check Sol. Valves connected to each port.

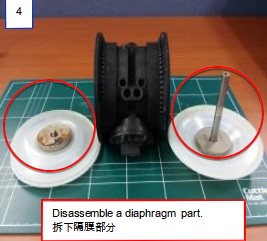

Water leakage of Air Pump Diaphragm

※ Check the leakage parts of the cover and diaphragm sides. Overhaul or replace diaphragms and assemble them in reverse order.

Water leakage from upper & lower parts of Air Pump O-ring

※ Assemble them in the reverse order after checking leakage or replacement of new diaphragm.

Air leakage from air valve side of Air Pump

※ Reassemble in the reverse order.

Article reprinted form:MarinSmart Platform

Author:After-sales Department—Mingqi Wang

Please indicate the source for reprinting articles

Scan the QR code to read on your phone

CONTACT US

WinKong Marine Engineering Co., Ltd.

Address: 15-19F, Zhongxin Building No. 263 Liaoning Road, Qingdao, Shandong Province, China, 266012

E-mail: newmkt@winkong.net

Fax: +86-532-83807505

Tel: +86-0532-83838072/+86-18863991891

Qingdao Free Trade Zone MarinSmart Supply Chain Co., Ltd.

Address: 8101-1-6(A), 1st floor, Qiantongyuan Building, No.44 Moscow Road, Qianwan bonded area, Shandong Province, China, SDPFTZ

Qingdao MarinSmart Technology Co., Ltd.

Address: 15-19F, No.263 Liaoning Road, Shibei District, Qingdao, Shandong Province, China

Qingdao Winkong Invest & Developing Co., ltd.

Address: 1702 Room, Zhongxin Building No. 263 Liaoning Road, Qingdao, Shandong Province

Qingdao MarinSmart Ship Design Institute Co., Ltd.

Address: 16F-B, No.263 Liaoning Road, Shibei District, Qingdao, Shandong Province,China.

Qingdao Global Marine Safetycare Technology Co., Ltd.

Address: Shandong University of Science and Technology, No. 579 Qianwangang Road, Huangdao district, Qingdao, Shandong Province,China.

MarinSmart Global Service Pte. Ltd.

Address: 2 Jurong East Street 21 #04-21C IMM Building Singapore 609601

© Winkong Marine Engineering Co.,Ltd. 鲁ICP备06011101号 Powered by 300.cn