Brief Discussion about Ship Fouling

- Categories:Technology

- Author:

- Origin:MarinSmartPlatform

- Time of issue:2022-03-25 14:46

- Views:

(Summary description)

Brief Discussion about Ship Fouling

(Summary description)

- Categories:Technology

- Author:

- Origin:MarinSmartPlatform

- Time of issue:2022-03-25 14:46

- Views:

Ship fouling and ballast water are the main way to introduce marine organisms into another geographically isolated water area.Once these marine organisms multiply rapidly in the local area based on the factors, such asstrong survival competitiveness themselves, natural enemies absence, local suitable living environment and other factors,which are very likely to destroy the local ecosystem, posing a threat to the local environment, economy and human health.

With the continuous growth of the international shipping trade and continuous enhancement of people's awareness of marine environmental protection, the problem of invasion of alien marine organisms brought by ships has attracted widespread attention.

The Australian Maritime Safety Authority (AMSA) believes that all international ships will pose a certain risk to Australia's marine life security. Once alien organisms are introduced and spread, they will threaten the local marine life habitat, affect local economy andhuman health. Therefore, AMSA announced that, AMSA will implement new management requirements forship fouling on internationalships planning to enter Australian territorial waters from June 15, 2022 to December 15, 2023. AMSA will control the security risk fromalien biological invasion on these ships through pre-arrival report assessment and on-site inspection.

Following isthe brief introductionon the causes, hazards, preventive measures and removal methods of ship fouling.

Some marine organisms that live in shallow waters, such as bacteria, shellfish, plankton, etc., have the characteristic of attaching to other objectsfor growing.These organisms may adsorb and gather on the part below the waterline of ship and "settle down" and breed.

Maybe somebody will ask:whythe sea water can not wash away these marineorganisms as vessel travel on the ocean?

Take barnacles as an example.Barnacles can secrete a sticky substance that enables them to stick to attachments firmly. Not only are they not afraid of the scouring of sea water, but they also rely on the fresh nutrients brought by the water flow, they embrace the challenge of water flow, also evolve themselves gradually. In addition to this, barnacles will also evolve to adapt the living environment, for example, produce stronger sticky substance,or attache to the sunken part of ship bottom wherewater disturbance is less.

Main cause of ship fouling

The degree of ship fouling is related tomultiple factors, such as the surface finish of the hull,ship coating,shipsailing rate, berthing time, sailing area,watertemperatureand salinity.

Rough hull surface is prone to attachment of marine organisms. Poor quality coating cannot prevent the attachment effectively. Low ship sailing, high water temperature and salinity are helpful to the attachment and breeding of marine organisms. Shipfouling increasesina linearrule at the initial time, and then its growth rate gradually slows down. Thedegree of ship fouling isbetterwhen vessel sailing in fresh water.

Ship fouling formed by largenumber of marineorganisms makes theshipbottom look like a moving seafood farm.

Effects and Hazards of Ship Fouling

In addition to ecological invasion, ship fouling will also have an impact on the operating cost and safety of the ship. Ship fouling makes the hull surface uneven, which greatly increases the sailing resistance and greatly reduces the sailing speed, which in turn leads to a great increase in fuel consumption and corresponding pollutant emissions. Local slightly acidic environment brought by biological metabolism will acceleratecorrosion of hull, which may affect the normal operation of seawater cooling system, depth sounder, log and sonar of the ship. This is a potential safety hazard for ships.

Shipfouling could result in an additional 110 million tons of carbon emissions and $6 billion in fuel bills per year for the global commercial fleet, extrapolated from data published in a 2011 study by Michael P. Schultz.

Our country once had an ocean-going freighter moored in Sicily, Italy. During 28 days, a large number of marineorganisms attached to the bottom of the ship.During the voyage, the speed was reduced from 18 knots to 13 knots, and the sailing time was also 10 more days longer than expected, resulting in a fuel consumption increase of 500 tons.

According tothe MarinSmart Platform,COVID-19 has caused port congestion and ship suspension in many countries and cities all over the wordsince 2020. The long-term idleness of ships has led to a significant increase in the severity of ship fouling.

Measures to prevent ship fouling

Small marineorganisms can cause such harm,and what methods can be used to preventthem?

1. Use coatings containing antifouling agents

The earliest anti-fouling agent kills attached organisms by releasing toxic compounds such as tributyltin and arsenic. Since 2008, the use of organotin antifouling coatings has been completely banned internationally. Tin-free antifouling agents such as copper, mercury oxide, and phenolic can effectively inhibit or even kill marine organisms. However, with the slow exudation of these toxins, it will also pollute the marine ecological environment.

The development trend of preventing ship fouling is to develop low surface energy anti-fouling coatings and bionic anti-fouling coatings. Among them, the application of silicone resin low surface energy anti-fouling coatings is relatively mature, which can effectively reduce the adhesion of marine organismson the hull, but there is a problem of high cost.

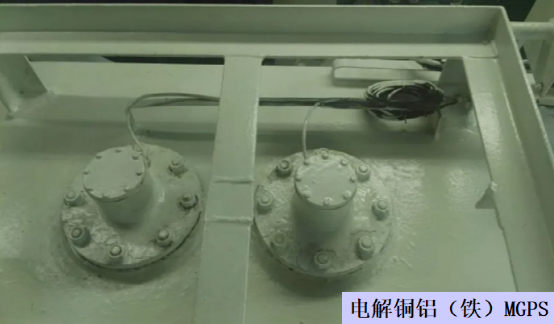

2.Use Marine Growth Preventing System (MGPS)

The purpose of MGPS is to prevent marine organisms from adhering tosome places such as ship bottoms,sea chest, seawater pipeline, seawater coolers, etc., as well as breeding and corrosion in these places.

MGPS typescommonly used include seawater electrolysis, copper-aluminum (iron) electrolysis and ultrasonic, or combined use.

Electrolysis type utilize electrolysis to produce effective chlorine and toxic metal ions to kill marine organisms, which need to replace electrode regularly. At the same time, chlorine and metal ions alsobring certain toxicity to the marine environment and human health. Ultrasonictype utilize the ultrasonic vibration and cavitation effect to generate a large number of small bubbles. When the small bubbles burst, instantaneous high pressure and high temperature will be formed in the surrounding area, which can quickly peel off the attachments formed by marine organisms and smash the epidermal cells of the organisms. It can effectively inhibit the attachment and growth of marine organisms,and has the advantages of environmental protection, energy saving, and easy maintenance.

Comparison of three MGPS types

|

Type |

Seawater Electrolysis |

Copper-aluminum (iron) Electrolysis |

Ultrasonic |

|

Principle |

Produce effective chlorine to kill marine organisms. |

Produce heavy metal ion to kill marine organisms. |

Using cavitation effect to kill marine organisms. |

|

Advantage |

Safety, stability and mature. |

Convenient for installation with simple structure. |

Safety with stability, installation with convenience, and wide application range. |

|

Key requirements |

Effective chlorine concentration control. |

Heavy metal ion concentration control. |

Installation layout and system numbers. |

|

Disadvantage |

Large power consumption;electrodes scale easily. |

Replace copper or aluminum rods regularly, with high maintenance cost. |

Cavitation effect may cause coating to fall off. |

|

Cost |

Higher initial input cost and operation cost. |

Low initial input cost,high operation cost. |

High initial input cost, andlowoperation cost. |

Ultrasonic type in seawater filter

Ultrasonic type in pipeline

In addition to "toxic coating" and MGPS, other methods also have been used to prevent fouling, such as the use of coatings containing biologically active substances, warm andfresh water treatments that artificially alter the living environment, freezing, ordirect use of hull materials that are not easilyattached by organisms, etc.

Regular ship bottom cleaning is inevitable, although people have adopted various methods to inhibit the formation of ship fouling.

Methods of removingShipfouling

There are three ways to clean the bottom of the ship. One isusing high-pressure water guns,orsandblastingin dock, which iscommonly known as scraping the bottom of the ship. This methodneed takesmuchtime, manpower, material resources and financial resources, but it canclean the ship thoroughly.

The second method is to hire divers trained in corrosion control and problem identification,who canassess the condition of ship bottomprofessionally. Divers can clean the hullusing high-pressure water guns or special equipment. This method hassome disadvantages,such as high operation difficulty, high safety risk, low cleaning efficiency, small operation coverage, possible damage tohullsurface, and inability to clean the bottom of ships with deep drafts.

The third method is to use an underwater cleaning robot, which allows the robot to clean the bottom of the ship underwater through wireless remote control. Especially in the special period ofCOVID-19 control,the advantage is that it doesn’t require contact with port and ship personnel, which will not affect the normal operation in ports.

This method is not very effective in cleaning thesea chest, propellers, rudders,sidethrusters, seawater outlet, and professional divers are also necessary to cooperate.

All above images are from the Internet.

Article author:MarinSmart Platform Expert Committee

Please indicate the source for reprinting "MarinSmart Platform"

Scan the QR code to read on your phone

CONTACT US

WinKong Marine Engineering Co., Ltd.

Address: 15-19F, Zhongxin Building No. 263 Liaoning Road, Qingdao, Shandong Province, China, 266012

E-mail: newmkt@winkong.net

Fax: +86-532-83807505

Tel: +86-0532-83838072/+86-18863991891

Qingdao Free Trade Zone MarinSmart Supply Chain Co., Ltd.

Address: 8101-1-6(A), 1st floor, Qiantongyuan Building, No.44 Moscow Road, Qianwan bonded area, Shandong Province, China, SDPFTZ

Qingdao MarinSmart Technology Co., Ltd.

Address: 15-19F, No.263 Liaoning Road, Shibei District, Qingdao, Shandong Province, China

Qingdao Winkong Invest & Developing Co., ltd.

Address: 1702 Room, Zhongxin Building No. 263 Liaoning Road, Qingdao, Shandong Province

Qingdao MarinSmart Ship Design Institute Co., Ltd.

Address: 16F-B, No.263 Liaoning Road, Shibei District, Qingdao, Shandong Province,China.

Qingdao Global Marine Safetycare Technology Co., Ltd.

Address: Shandong University of Science and Technology, No. 579 Qianwangang Road, Huangdao district, Qingdao, Shandong Province,China.

MarinSmart Global Service Pte. Ltd.

Address: 2 Jurong East Street 21 #04-21C IMM Building Singapore 609601

© Winkong Marine Engineering Co.,Ltd. 鲁ICP备06011101号 Powered by 300.cn